Sequential vs. Traditional Gearboxes: Which is Best for Your Truck?

Sequential vs. Traditional Gearboxes: Which is Best for Your Truck?

Sequential vs. Traditional Gearboxes: Which is Right for Your Truck?

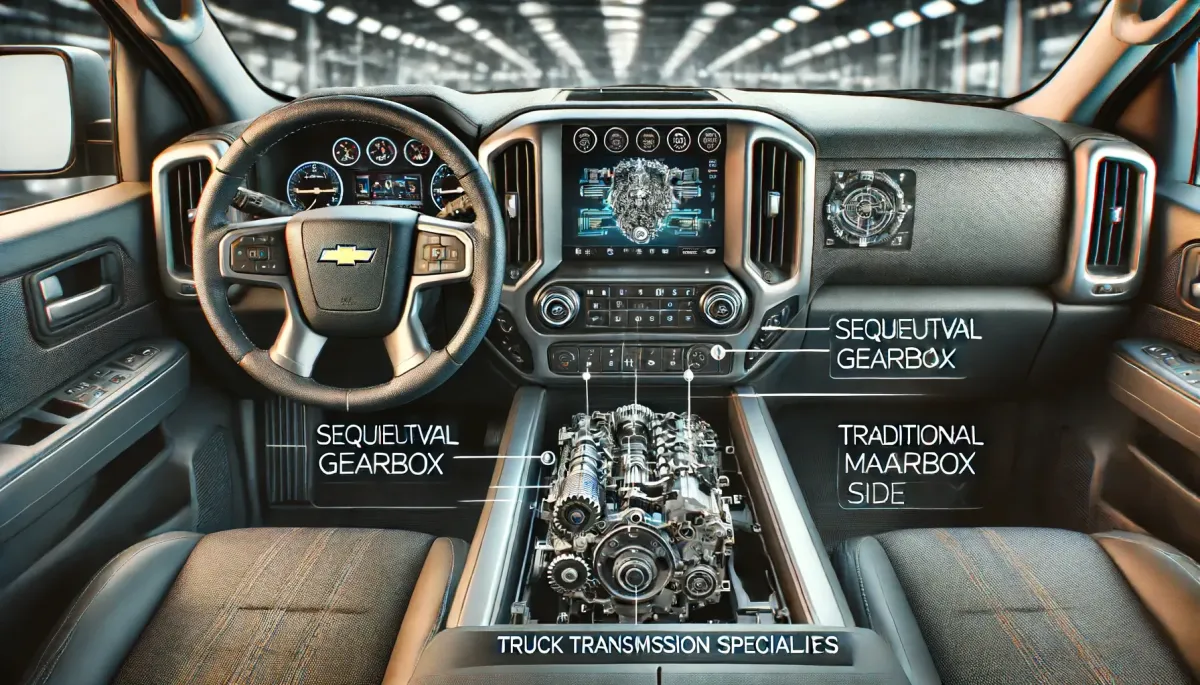

When it comes to truck transmissions, the choice between a sequential and a traditional gearbox is a big one. It can significantly impact your truck's performance, driving experience, and even your wallet. At Truck Transmission Specialists, we're here to break down the pros and cons of each to help you make the best decision for your needs. Let's dive in!

Sequential Gearboxes

Sequential gearboxes are all about lightning-fast gear changes and maximizing power delivery. They operate on a simple principle: gears are shifted in a predetermined sequence, either up or down, one gear at a time. This linear shift pattern, often facilitated by a specialized sequential shifter, eliminates the need for the driver to think about selecting the next gear, making it incredibly efficient, especially in performance driving situations.

Here's what you need to know about sequential gearboxes:

Shifting: Gears are changed in a specific order (up or down, one at a time) using a sequential shifter.

Clutch: Many sequential gearboxes incorporate an automatic clutch system controlled electronically, further simplifying the driving experience.

Applications: Commonly found in high-performance vehicles and heavy-duty trucks where quick acceleration and optimal power transfer are essential. Think Ford's F-150 Raptor or Dodge's Ram TRX.

Gear Ratio: Optimized for specific performance scenarios, often with closely spaced ratios for maximum acceleration.

Cost and Maintenance: Can be more expensive than traditional gearboxes and may require specialized maintenance due to their complex design.

User Engagement: Offers a more streamlined driving experience with less manual input required for shifting, making them easier to operate, particularly under demanding conditions.

Traditional Gearboxes

Traditional gearboxes, also known as manual transmissions, have been the mainstay in trucks for decades. They offer drivers a direct connection to the vehicle's powertrain, allowing for complete control over gear selection. While they may not shift as rapidly as their sequential counterparts, traditional gearboxes provide a level of flexibility and engagement that many drivers appreciate.

Here's a closer look at traditional gearboxes:

Shifting: Allows the driver to select any gear directly using a gear stick. This H-pattern shifting pattern provides the flexibility to skip gears (when appropriate) but requires skillful clutch use and gear matching for smooth and efficient operation.

Clutch: Employs a manual clutch pedal controlled by the driver, necessitating precise coordination between clutch engagement and gear changes.

Applications: Found in a wide range of trucks, from daily commuters to heavy-duty haulers. Their cost-effectiveness, ease of maintenance, and familiarity make them a popular choice in vehicles like the Chevrolet Silverado and GMC Sierra.

Gear Ratio: Offers a broader range of gear ratios, providing flexibility for various driving conditions, from towing heavy loads to navigating city streets.

Cost and Maintenance: Generally less expensive to manufacture than sequential gearboxes, resulting in lower purchase costs and typically less specialized maintenance.

User Engagement: Provides a more engaging driving experience due to the active use of the clutch and the skill required for smooth gear changes. This hands-on approach gives drivers a greater sense of control over their vehicle.

Making the Decision

Deciding between a sequential and traditional gearbox ultimately boils down to your needs and priorities. Consider these factors when making your decision:

Performance: If you crave raw speed and acceleration, a sequential gearbox will deliver exhilarating performance.

Driving Style: Do you prefer a more engaging driving experience, or do you prioritize ease of use and convenience? Traditional gearboxes offer greater driver involvement, while sequential gearboxes simplify the shifting process.

Budget: Sequential gearboxes tend to be more expensive than their traditional counterparts, both upfront and in terms of long-term maintenance.

Typical Driving Conditions: Consider where you drive most often. Sequential gearboxes excel in performance settings, while traditional gearboxes offer versatility for a wider range of driving situations.

No matter your choice, Truck Transmission Specialists is here to help. We specialize in rebuilding and servicing both sequential and traditional gearboxes for all makes and models of US domestic trucks. Our team of expert technicians, including Luke Harrison and Tyler Spangler, has 18 years of experience and is dedicated to exceeding OEM standards in every rebuild. Call us at +1 385-462-8458 or visit prebuilttrans.com to learn more about how we can keep your truck running smoothly!

© 2024 Truck Transmission Specialists. All rights reserved.